Our Mission

To be a global leader in production of state of the art Less Lethal munitions, in consonance with Make – In- India policy of the Government of India, through sustainable growth, knowledge, excellence and exemplary governance practices.

Genesis & Growth

TSU was formally established at Tekanpur on 12 May 1976 as a project of the Ministry of Home Affairs, to produce Tear Smoke Munitions Till then, Police forces in India were dependent on imported TSMs for law enforcement purposes. Establishment of TSU thus enabled availability of indigenous ‘Less Than Lethal Munitions’ eventually ending dependence on foreign munitions.

TSU started with the production of four types of TSMs and presently has expertise in manufacturing more than 46 types of munitions. Backed by robust R&D setup, strong quality processes and rich experience of managing clients across the world, TSU aligns production strategies with customer requirements. From simple changes in process to innovative solutions, the unit helps customers harness the power of less than lethal Munitions to achieve excellency, customer satisfaction and sustainability. The products developed by the TSU have esteemed positions in the Catalogue of Jane’s Police and Security equipment manuals.

Tear Smoke Unit envisions to be a global leader in Production of State of the Art less than lethal Munitions through sustainable growth, knowledge excellence and exemplary governance practices. Underpinning this vision is a performance culture committed to achieving targets, safety and social responsibility, continuous improvement, innovativeness and transparency.

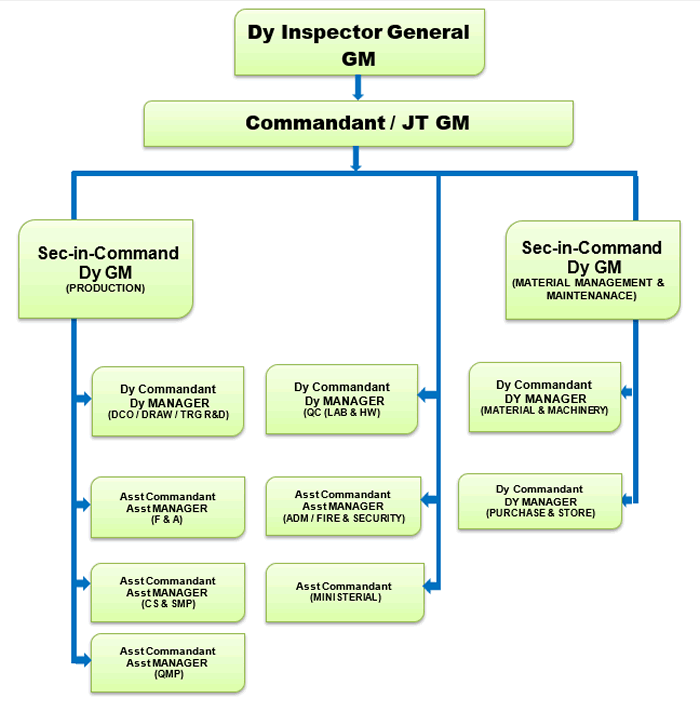

Management Profile

Our Vision

- To equip our Police and Armed Forces with Less than lethal munitions to deal with various law & order and peace time operational situations.

- To Continuously Modernize our Production Facilities.

- To equip ourselves with Technologies through Synergy and In-house R&D.

- To Continuously Improve Quality.

- To improve operational efficiency.

- To continuously achieve highest level of customer satisfaction.

Planning

To bridge the gap between demand and supply, TSU has enhanced its production capacity to 12 times, by adopting innovations and best management practices. TSU is aiming to further enhance the production capacity to meet increasing demand of TSU products through capital infusion and automation process.

Research & Development

TSU has an excellent R&D set up which continuously strive to improve existing products and invent new products as per security forces requirements. This year (2020-21) 10 new products developed by TSU have been tested and approved by BPR&D for use by law enforcement agencies of India.

Our Quality Policy

TEAR SMOKE UNIT (TSU) is committed to produce products that meet customer and legal requirements by optimal use of resources to attain customer satisfaction and confidence through the application of the quality management system and its continual improvement. TSU has decided to achieve established QUALITY OBJECTIVES and such objectives are periodically reviewed.

Our Quality Objective

In line with the Quality Policy of our organization, we have decided to achieve following Quality Objectives, which are established at various functions and levels within our organization.

- Customers’ satisfaction/confidence in its products.

- Delivery on time and timely production.

- Human resource Development (In-house training and external training).

- Effective internal and customer communication.

- Supplier Development and timely valuation/re-evaluation of supplier.

- Safety, good health and hygiene of personnel and a clean environment to prevent accidents.

- Waste management to reduce wastage, re-work and rejection.

- Pollution control and

- Continual improvement in the quality management system

Patent of TSU Products

Lachrymatory Composition Comprising PAVA for Riot/Crowd Control Measures

Reusable Training Simulator Shell for training

Tear Smoke Wood Piercing Shell.

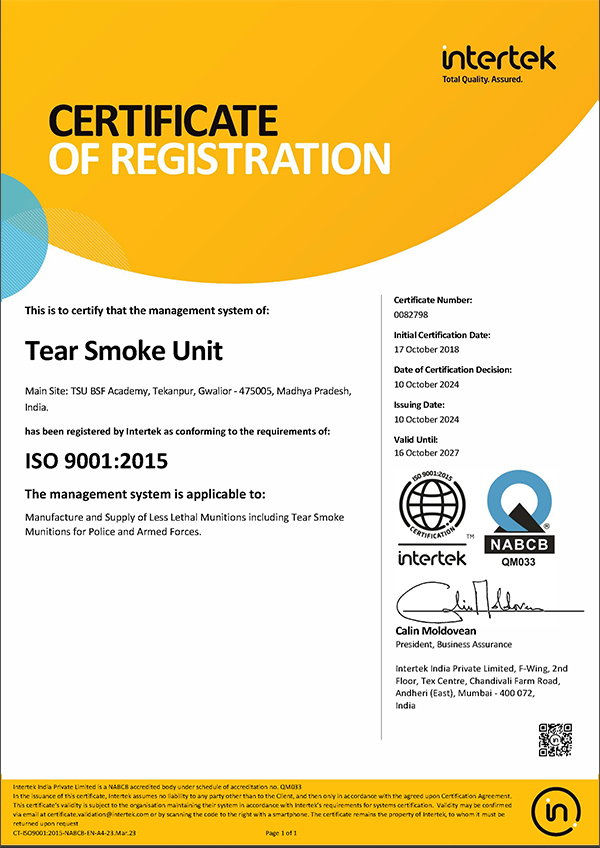

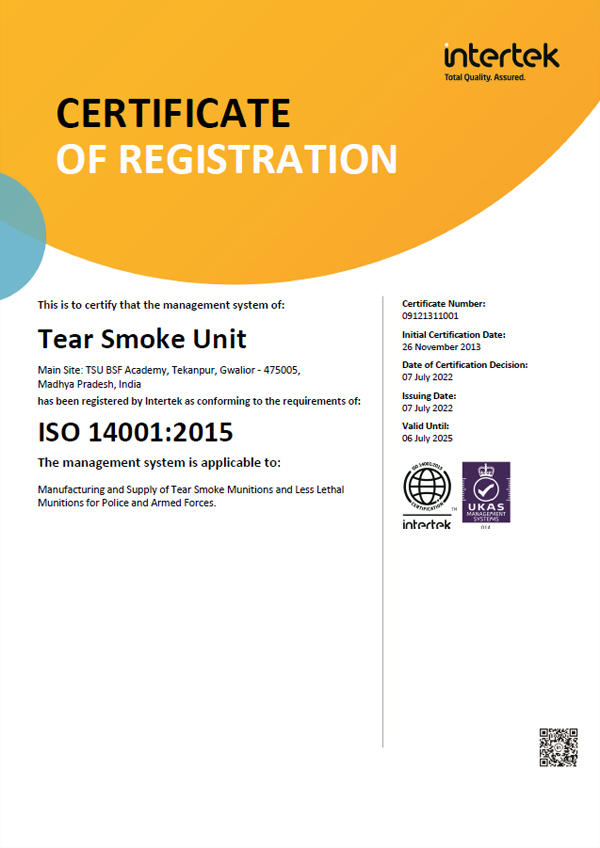

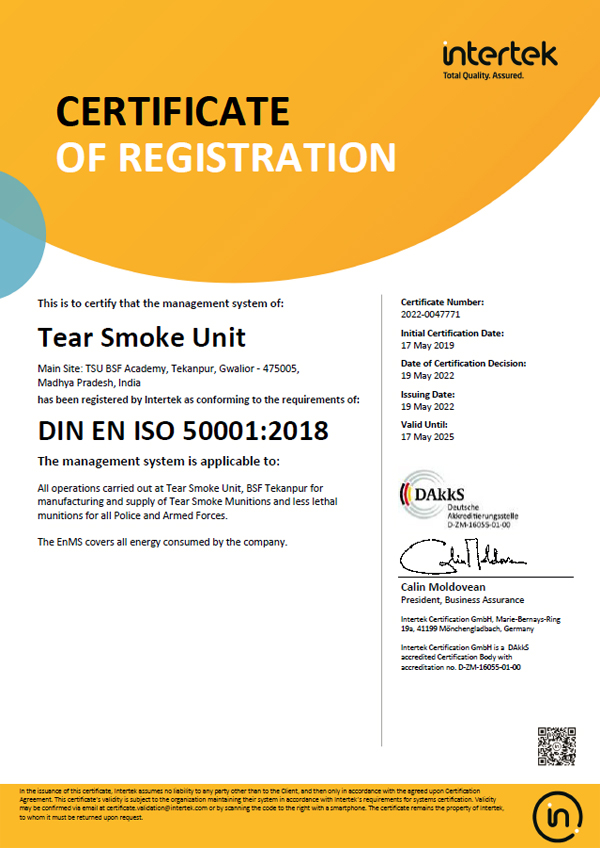

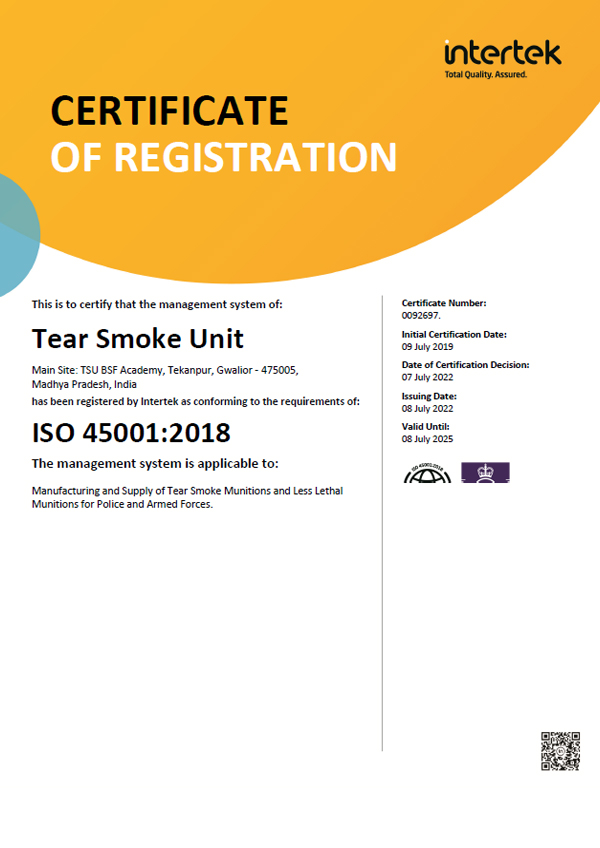

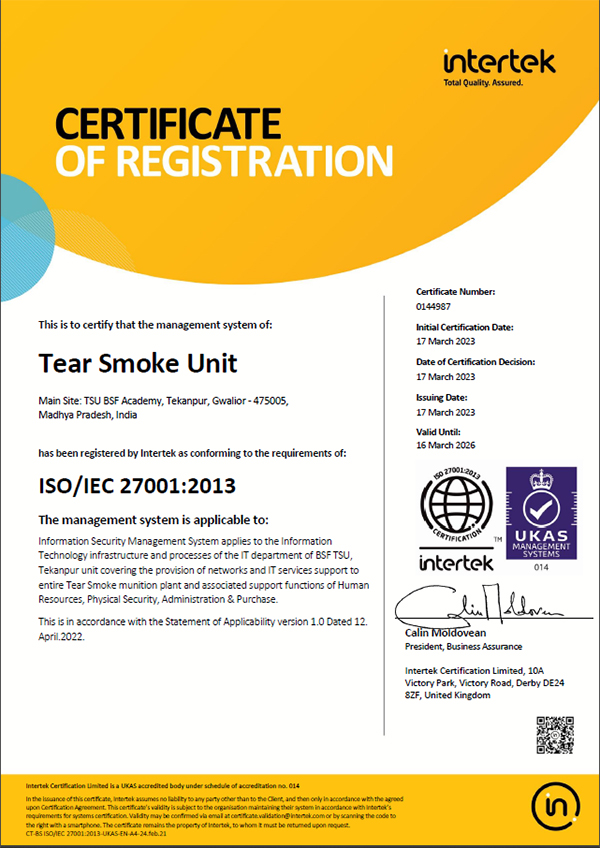

Certifications

TSU is certified with all five major ISO certificates, which bear testimony to professional competence of TSU and quality of its products.

ISO- 9001:2015

(Quality Management system)- Sept’ 1998

ISO-14001:2015

(Environmental Management System)- Nov’ 2013

ISO-50001:2018

(Energy Management System)- May’ 2016

ISO-45001:2018

(Occupational Health & Safety Management System)- July’2019

ISO/IEC-27001:2013

(Information Security Management System) - March 2023

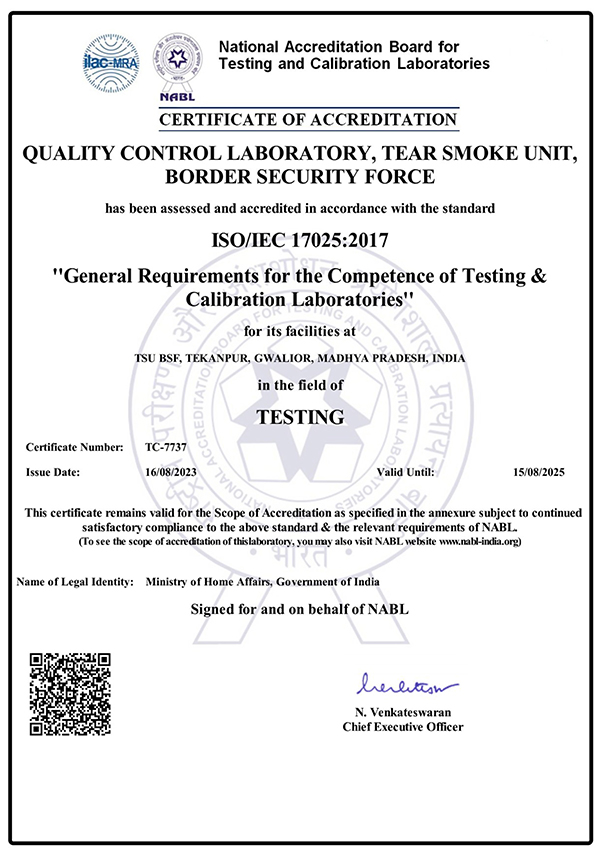

NABL Accreditation

NABL Accreditation (ISO/IEC-17025:2017) for PLASTIC TESTING- Aug’2018 with ILAC-MRA (International Laboratory Accreditation Cooperation-Mutual Recognition Arrangement) Mark

FIRE SAFETY CERTIFICATE

TSU is awarded with fire safety certificate from “National Institute Fire & Safety Engineering, Gwalior(M.P)” & “Municipal Corporation Gwalior(M.P)” in 2024.

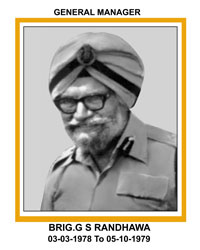

Our former General Managers

MAJ.GEN.H C GAHLAUT

12-05-1976 To 12-03-1978

BRIG.G S RANDHAWA

SHRI K S RATHORE, IPS

MAJ.GEN.J B ISWARIAH

SHRI R K SACHAR SM, IPS

SHRI A K SARBADHIKARY

Dr. G P BHATNAGAR

SHRI N S YADAV

SHRI S C MAHAJAN

SHRI NARESH MAHARA

SHRI S K VIJ, IG

SHRI J P SINHA

SHRI V K PANDEY

SHRI R M KADIAN

Dr. SABU A JOSEPH

SHRI EDWIN JOHN BENNET

SHRI B C NAIR

01-05-2019 To 31-05-2023

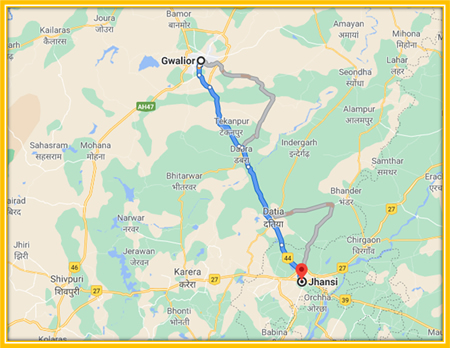

Geographical Overview

Tear Smoke Unit is located on Gwalior Jhansi road astride NH-75 at a distance of about 30 Kms from Gwalior. The nearest Railway Station is Dabra which is 14 Kms from Tear Smoke Unit and the nearest Airport is at Gwalior.